UNMANNED WEIGHBRIDGE SYSTEM

Unmanned Weighbridge System

- is a standalone system which allows 24 hours 7 days a week weighing operations without the need of operator. Due to the system’s easy interface it is totally operated by the truck driver. Moreover PUNIT INSTRUMENT Solution custom designs the system to suit the specific requirements of your operations..

- PUNIT INSTRUMENT Provide Two Way Weighbridge Automation System, Two Way means vehicle enter both side for weighment. also we can pre fix weighbridge for weighment if they try another weighbridge system cannot allow to weighment.

- PUNIT INSTRUMENT Weighbridge Automation System Software is a intelligent solution that turns your weighbridge Fully Secure, Automated and Operator Less Means eliminating the need of weighbridge operator. The system can be customized with many add-ons like camera plate recognition, surveillance cameras, traffic barriers, traffic lights, etc.

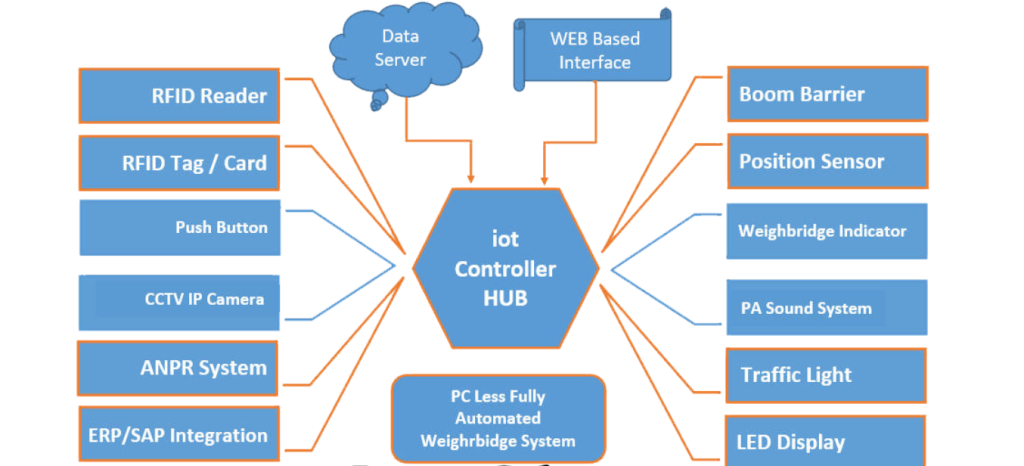

System Integrate :

- iot Based UMS Controler

- Vehicle Position System

- CCTV Camera & Photo Capturing

- Barrier Security system

- Instruction Announce with loud speaker

- Integrate with SAP, Oracle, ERP

- RFID Integration

- Barcode Integration

- PLC Based Intelligent Indicator

- Traffic light indication

- Photo sensor based system

- Automatic vehicle weighing software

System Working For :

- Quarries

- Mining Industry

- Steel Industry

- Cement Industry etc.

- Sugar Industry

- Landfills

- Waste Recycling

- Agriculture

Key Features :

- Unmanned Weighbridge System and software

- iot Based UMS Controler

- Robust and weather-proof stainless steel cabinet for added protection with optional climate control.

- CCTV Camera Supporting.

- Data accuracy with pre-programmed vehicle data using RFID card readers or Touch panel with user friendly interface.

- Improved facility control and security with traffic barriers, traffic lights, surveillance cameras etc

- Weighing Data Management Software interacting with PUNIT INSTRUMENT industrial scale terminals provides instant access to critical business information such as operational analysis, billing and inventory control.

- Weighing Terminal with RFID Card Reader or Touch Panel Terminal – for accurate and quick data input

- Detection Loops or Photocells – to automatically detect vehicles and transfer of details.

- Traffic Lights – For safe operation

- Exit & Entry Barriers – For security and arranging vehicle traffic.

- Truck Plate Recognition – For clear identification of vehicles and loads.

- Surveillance Cameras – For increased security

Advantages :

- Removes Weighbridge operators From Weighbridge Office

- Cut Weighing Operating costs with a Fully Automated Vehicle Weighing Solution

- Reduce TAT ( Tern Around Time ) for busy weighbridges

- Fully integrate solution into you Back Office Systems Like ERP, SAP, ORacle Etc..

- Automatic identification of Driver (Biomatrix), Truck, Trailor With RFID and ANPR System

- User UHF(Long Range) & HF(Short Rnge) RFID Reader For Autoamtion System

- Stop malpractice and Theft Process at Weighing Station

- Redure Weighing Time 5 Min to 45 Sec For One Weighing

- Remove PC From Weighing Office Using Out iot Based Smart Controller

- Reduce PC Cost and PC Manatenace Cost

- Web Based Interface For Automation system To Easy to use and Deskboard For One Click Information

iot Based Smart Controller :

- PUNIT INSTRUMENT Provide Two Type Unmanned Weighing System : 1) PC Based Unmanned Weighing Solution, 2) PC Less Unmanned Weighing Solution

- PC Less Solution Design Based on iot Smart controler

- iot Controller Connect All Require Hardware Like Boom Barrier, Traffic Signal, LEd display, Sound PA system, RFID Reader, cctv ip Camera, Weighing Indicator etc.

- iot Based System is Pc Mentenance Free

- iot Controler is Communicate With Server System and Make Secure Weighing

- Provide WebBased Interface For access iot smart Controler from it office

- iot Smart controler Display all hardware working Status