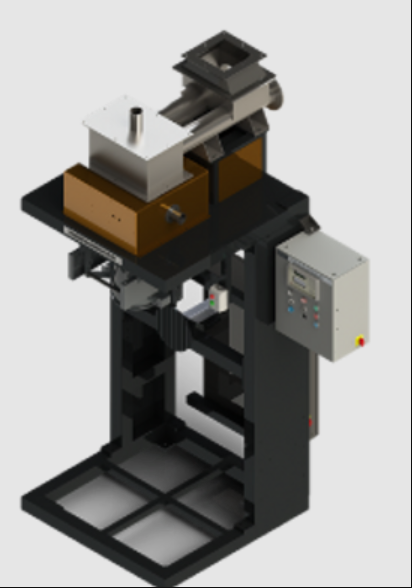

Powder Bagging system

Description

The Powder Bagging system is Suitable for High-Speed bagging of dry and free-flowing powders (Starc, Maida, Flour, Fine sugar, Chemical )

Knowing the Materials

-

The first vital, most important step is to know the flow-ability of your material, commodity that is being bagged.

-

Is it granular solids? Is it powder? Is it free-flowing? Is it dry or it has moisture (sticky)?

-

Can the material easily flow down the hopper by gravity without sticking to the surface? Or whether it requires a forced feeding mechanism i.e. screw feeder?

-

Even little amount of sticking to surface could affect weight accuracy, since what is weighed does not fully gets discharged into the bag

Features

-

Easy to install

-

Accurate weighing-No excess , no shortage

-

Eliminates Human errors

-

Higher productivity

-

Low operating cost

-

Easy maintenance

-

Flexibility to run different bag capacities with a single machine

-

Interlock sensors to avoid accidental spillage/wastage of material

-

Model AWSFS-PBS (Approved By Weights And Measures Department)

-

Product Handled Chemical Powder,Activated Carbon,Dolomite,Flour(Maida,Atta),Coffee Powder

-

Bag Capacity Bagging From 25kg To 50kg

-

Accuracy : ±100gms

-

Bags/Hour: 100-150 Bags/Hr(50kg)

-

Bag Type Open Mouth-Cloth,Jute,LDPE,HDPE,Paper

-

Feeder Mechanism Speed And Accuracy Achieved With Double Screw Conveyors(Coarse & Fine Filling)

-

Bag Clamping Mechanism Pneumatically Operated With Foot-Lever Or Hand Lever For Easy Single Person Operation.Discharge Chute And Clamp Is Designed For Strong Grip On The Bag Without Sliding During Loading Of Material

Reviews

There are no reviews yet.